|

|

|

|

|

Plate Jacks®, Permanent Installation—

Over 3,500 RPS Jacks are in place in major structures providing permanent

support or load distribution.

|

- Transfer the weight of buildings and bridges to retrofitted seismic isolators

- Replacement of bridge or roof bearings

- Redistribution of reactions in undesirable deflections

- Preloading new structural elements in existing structures

- Interface between structure and foundation in large block assembly

- Permanent shimming

|

|

|

|

Los Angeles City Hall—534 RPS Plate Jacks™, in capacities from 500 kips to 6,100 kips were used to transfer the weight of this building to retrofitted seismic isolators.

|

|

Los Angeles City Hall

RS 6100 Plate Jacks™ over seismic isolators

in Los Angeles City Hall

|

|

Campbell Hall, Western Oregon State College, Monmouth, Or—RS 400 and RS 240 Plate Jacks™ were used to transfer the weight of this historically important unreinforced masonry building to seismic isolators. Because of the compressibility of the foundation soils, the jacks were initially extended with oil, and settlement monitored and corrected periodically until stability was achieved. The jacks were then solidified by transfusion with epoxy. Campbell Hall, Western Oregon State College, Monmouth, Or—RS 400 and RS 240 Plate Jacks™ were used to transfer the weight of this historically important unreinforced masonry building to seismic isolators. Because of the compressibility of the foundation soils, the jacks were initially extended with oil, and settlement monitored and corrected periodically until stability was achieved. The jacks were then solidified by transfusion with epoxy.

|

|

Campbell Hall, Monmouth, OR

RS 400 Plate Jack™ over lead-rubber isolator

Campbell Hall

|

|

|

Floating Production Storage and Offloading (FPSO) Vessel Brazil—Sixteen RS 1915 Plate Jacks, hydraulically manifolded to equalize thrust, were extended using epoxy to position the production turret in the hull of this converted tanker, and to assure equal loading to all support pedestals under the main bearing.

FPSO Tantawan Explorer, 1996, Gulf of Thailand

FPSO P-33, 1997, Marlim Field,Offshore Brazil

FPSO P-35, 1997, Marlim Field, Offshore Brazil

FPSO Espadarte, 1999, Offshore Brazil

FPSO Brazil (Roncador), 2002, Offshore Brazil

FPSO White Rose, 2003, Offshore Newfoundland

FPSO Marlim Sul, 2004, Offshore Brazil

|

|

Turret, FPSO Brazil

Turret support pedistals, FPSO Brazil

RS 1915 Plate Jack™ in place on pedestal,

bearing inclined 35 degrees |

|

|

Braddock Locks and Dam—The precast sections for this new dam were floated into position and ballasted down onto a preinstalled pile foundation. RS2100 Plate Jacks™ stacked in pairs to provide a 2" possible lift, were used to level and vertically align the sections, and to properly distribute load to the various piles.

|

|

Braddock Dam, Monongahela River at Braddock, Pennsylvania

|

|

|

Midtown Station, MARTA, Atlanta, Georgia—RPS installed 56 RS 500 calibrated transfusion jacks with integral PTFE/stainless sliding bearings at 26 locations to replace the existing elastomer bearings which had failed under this 3,500 ton waffle slab roof. RPS built an electronic data acquisition system to simultaneously monitor hydraulic pressure at all locations, allowing reactions to be balanced for optimum structural stresses. After load balancing, jacks were transfused with epoxy for permanent installation.

|

|

Pair of RS 500 Plate Jacks™ manifolded together at one bearing location

Jack with local pressue gauge and transducer to trasmit to data acquisition system

|

|

|

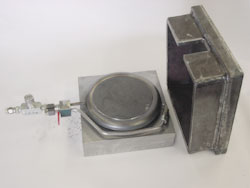

Seattle-Tacoma Airport, Washington—RS 080 bridge bearing with shear box to transmit horizontal shear loading

|

|

Disassembled

Assembled

|

R.P. Stagg & Co.. Inc.

1215 Michigan St, San Francisco, CA 94107

(+1) (415) 648-7171

Contact us for a comprehensive project history.

|

|