|

|

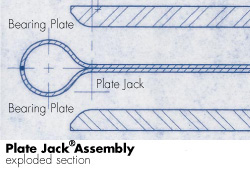

RPS Plate Jacks® are steel bellows jacks having flat bearing surfaces, and configured to provide a linear pressure / thrust relationship throughout the extension range. The bellows is sandwiched between bearing plates shaped to fit the contours of the bellows shell, and is provided with injection and vent ports configured to suit a particular application. The bellows shell is normally manufactured of low carbon steel, although stainless steel or Monel are used for applications in corrosive environments. Bearing plates are usually mild steel, but may be provided in a variety of metallic or polymeric materials to meet specific requirements.

|

|

|

|

All standard jacks have an unextended height of 1 1/4", and a rated extension of 1". |

|

|

|

RPS Plate Jacks® have a variety of applications in permanent or temporary installation, including redistribution of reactions in structures, leveling of structures or machinery, load transfer seismic isolators, replacement of bridge bearings, use as pressure or load cells, pre-loading replacement or new beams or columns in existing structures.

|

|

—backed by extensive experience in structural and foundation engineering, and in load transfer operations

|

|

|

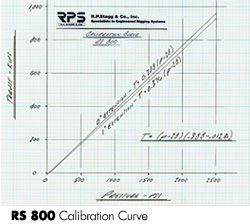

RPS Plate Jacks® provide a nearly constant thrust

for a given pressure over the complete range of expansion. The relationship for thrust as a function of pressure and expansion is linear, and is available for all jacks. Jacks to be used as pressure or load cells are individually calibrated against electronic devices having NIST traceable calibrations.

|

|

|

|

|

RPS Plate Jacks® may be installed in any orientation.

Jacks intended for non-horizontal application can be provided with bonded bearing plates and ports configured for proper fluid injection and venting.

|

|

|

|

|

|

|

RPS Plate Jacks® can be activated as temporary devices, or as a permanent part of a structure, using a variety of non-hardening or hardening injection fluids

RPS Plate Jacks™ may be kept active for an extended period

to adjust for time dependent variation of load or settlement by initially extending with a non-hardening fluid, then solidified while holding pressure and extension constant by displacing the initial fluid with epoxy or cementitious grout,a process referred to as “transfusion”.

|

|

|

|

| RPS Plate Jacks® |

- Are available in a large range of sizes from the small 18 kip jack used in millwright applications, up to the massive 6,100 kip jack.

- Have light weight for load capacity.

- Apply a bearing pressure within the allowable for most concrete and masonry structures.

- Can be installed and activated in remote locations, such as in submerged applications, or embedment in foundation elements.

- Conform to non-parallel bearing faces.

|

|

|

RPS Plate Jacks® are completely manufactured at our plant in Covington, Louisiana,

allowing rapid response to your unique application and configuration requirements.

|

|

RPS Plate Jacks® are proof tested to 120% of rated capacity

prior to shipment, and tagged with a unique identified for quality tracking.

|

|

RPS provides complete injection systems for use with oil, water, epoxy

or cementitious grout injection, complete with digital or analog pressure monitoring and recording devices.

|

|

R.P. Stagg & Co.. Inc.

1215 Michigan St, San Francisco, CA 94107

(+1) (415) 648-7171

contact us

|